Refrigeration and cooling is the production and distribution of a very important link. With the future of the frozen food industry continues to grow and cooling requirements , more and more food processing companies will enhance or expand its refrigeration and cooling lines. Currently Development Day Xingyue different food freezing technology , the traditional mechanical refrigeration equipment is being replaced by food and many more new food freezing equipment and technology advantage. Frozen Food technology today can be classified into three categories, namely: mechanical food freezing equipment , cryogenic food freezing equipment , the impact of food refrigeration equipment .

Mechanical food freezing equipment

Use of a refrigerant ( ammonia, usually ) closed circulatory system by indirect heat exchange to reduce the air temperature of the food and the food . The first device of its equipment used in food production, the majority of frozen food processing line used . Its working principle is : the indirect heat absorbed by the food closed loop system , the heat is transferred to the circulatory system of the condenser section and indirect air or water discharged through the high pressure liquid refrigerant is heat introduced into the circulatory system the evaporator section , when the refrigerant passes through the expansion valve in the circulation system , cooling the gas to become vaporized state , the gas refrigerant of low temperature and pressure will again be closed circulation system trip. The use of relatively high temperature refrigerant , the heat conduction rate of the process is slow.

Impact Frozen Food

It is the direct impact of a food processing equipment by a high speed jet. Products that have been fixed and placed on a conveyor belt of high pressure air DC shock. High-pressure air from above ( as well as from below ) through the slots , holes or short tube oriented foods, high-speed air to break the food surface interface , improved thermal conduction. Its thermal conductivity rate faster, but requires that food does not need a flat above 20mm.

Cryogenic food freezing equipment

Cryogenic food freezing equipment although recent technology development results , but has been globally important food processors successfully. Often using liquid nitrogen (-196 ℃), applied directly to the food . These ultra-low temperature refrigeration systems are usually foods are food processors to use, its initial investment in fixed assets compared to mechanical, impact the amount is smaller. Between the surface of the food due to high temperature and the difference between the refrigerant present in the thermal conductivity at a faster rate .

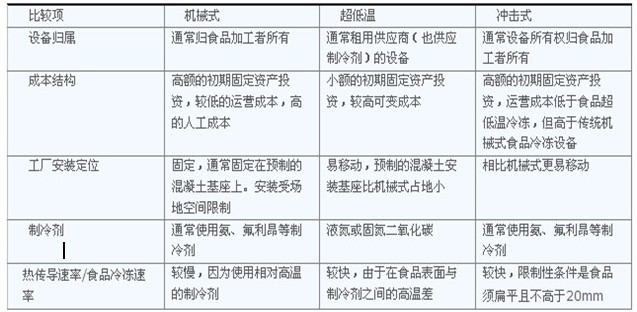

The main features of various types of food freezing process and compare the following table :